Reliability & Performance Programs

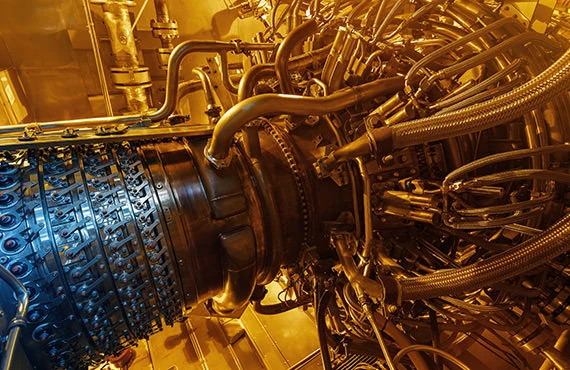

Monitor the health of your critical equipment, from pumps and compressors to fans and turbines.

We provide a consummate list of services and solutions for all of your rotating equipment reliability needs.

Monitoring the health of your critical equipment, like pumps, compressors, fans, and turbines, is an important component in achieving production goals and achieving operational certainty. Puffer Guyana helps you hit your targets.

PORTFOLIO OF Reliability & Performance Services

(click to expand)

AOV Diagnostics

Reach optimum efficiency and reliable valve performance

Control valve problems are common in all industries. AOV diagnostics quickly finds most valve problems, set-up and calibration problems and training deficiencies all from a non-intrusive standpoint.

Graphical results combined with valve expertise give a picture into what is happening in the valve. AOV diagnostics has been utilized all over the world in many different applications and has helped customers reach optimum efficiency and reliable valve performance.

Asset Optimization Program

Let’s develop a site-specific Pressure Relief Valve Asset Optimization Program

Puffer Guyana can effectively manage these programs, also known as spare valve pool programs, which can be a game changer for your operation. It opens new and innovative approaches to managing maintenance cost and process equipment reliability.

We can utilize existing customer assets to reduce new product spend, save 30-50% with expedited repairs to have valves serviced and material sourced on a routine non-expedited basis, and reduce overall maintenance or turnaround work orders by having valve spares on the ground at the time existing equipment is removed.

Check Valve Diagnostics

A non-intrusive method to determine valve performance and operability

With Puffer Guyana, diagnostics can be performed online to cut maintenance or replacement costs, reduce down time and simply get it done faster than traditional means.

In-Situ Relief Valve Testing

Ensure your rotating assets are functioning to safeguard life and protect property

Failure of valves can result in serious damage to vessels, exchangers, boilers, equipment, even human life.

Periodic testing ensures pressure safety and relief valves remain in good working condition and are protected. Our In-Situ testing subjects valves to full operating endurance conditions, testing all types and sizes of valves onsite with minimal interruption.

Puffer Guyana analyzes failures down to latent root causes, which include physical (mechanical/electrical) and organizational (human) levels. We offer expertise in the SAE-JA1011 methodology, and can provide you with formal consultations on Failure Mode and Effects Analysis (FMEA) and Reliability Centered Maintenance (RCM) processes.

Leak Detection

Pinpoint the source of process leaks and validate the economic impact across a system

Puffer Guyana can determine which valves are most economically feasible to repair to maximize the impact of the maintenance budget. The results are ranked by financial impact using heat rate or MW Output recovery. We then come back and quantify the effectiveness of repairs.

This service is performed while the plant is online and can be utilized to validate outage scope. Valve team scope to repair seat leakage that is determined to be not financially justifiable may be able to be removed from the outage.

MOV Diagnostics

Achieve reliable and predictable valve performance

MOV diagnostics can be used to identify issues prior to failure. Our State-Of-The-Art technology provides a fast, accurate health report of both actuator and valve all from a non-intrusive means. The types of valves that can be diagnosed are Gate, Globe, Butterfly, Ball, Wedge Plug, and Double Block & Bleed for a wide range of other specialty applications.

Common Failure Items:

– Stem Nut Wear past 50%

– Bearings

– Gears

– Valve Stem

– Valve Internals

– Elect. Components

– Torque / Thrust Output

Outcome Based Services

Stay on schedule, keep within budget, hit quality goals, keep people safe

No matter your goals, Puffer Guyana’s team of project experts has deep experience in supporting process control systems and offers a wealth of services that focus on enhancing the reliability, functionality, and continued operation of your control systems.

Our staff is factory trained and carries exclusive certifications and is available to support a range of services from small additions of several control loops to new grass-roots facilities.

We provide complete project management services – from control system design to checkout, startup support, and planned preventive maintenance. Collectively we are familiar with all kinds of control systems and can support all aspects of your project.

Preventative Maintenance Programs

Baseline data collection indicates how ready your operation is for max production

Not all assets are alike. Nor do they operate in the same conditions or environments. That’s why Puffer Guyana has taken a programmatic approach when considering preventative maintenance techniques and developing work plans. We can let the application determine when and what type of maintenance to perform.

Detailed work instructions are built for a specific component and addresses that components needs as observed through the program. This helps customers better predict maintenance budgets all while ensuring the proper maintenance is being performed at the correct intervals.

Vibration Analysis

The most accurate and reliable diagnostics available for your rotating equipment

Vibration diagnostic techniques based on sound engineering principles are proven methodologies.

Vibration Diagnostic Services

Puffer’s proven field methodologies employ accurate vibration diagnostic techniques based on sound engineering principles. This ensures the most accurate and reliable diagnostic conclusions available for your rotating equipment.

Lube Oil Analysis

We offer an experienced service that uses a multi-purpose portable measurement tool that combines abnormal wear metals analysis, particle counting, viscosity and IR spectroscopy into a compact transportable system. Our specialists interact with your organization to identify the root cause for the best leading indicator of machinery health. This service is more comprehensive that mere oil analysis, it’s a partnership with knowledgeable people who care.